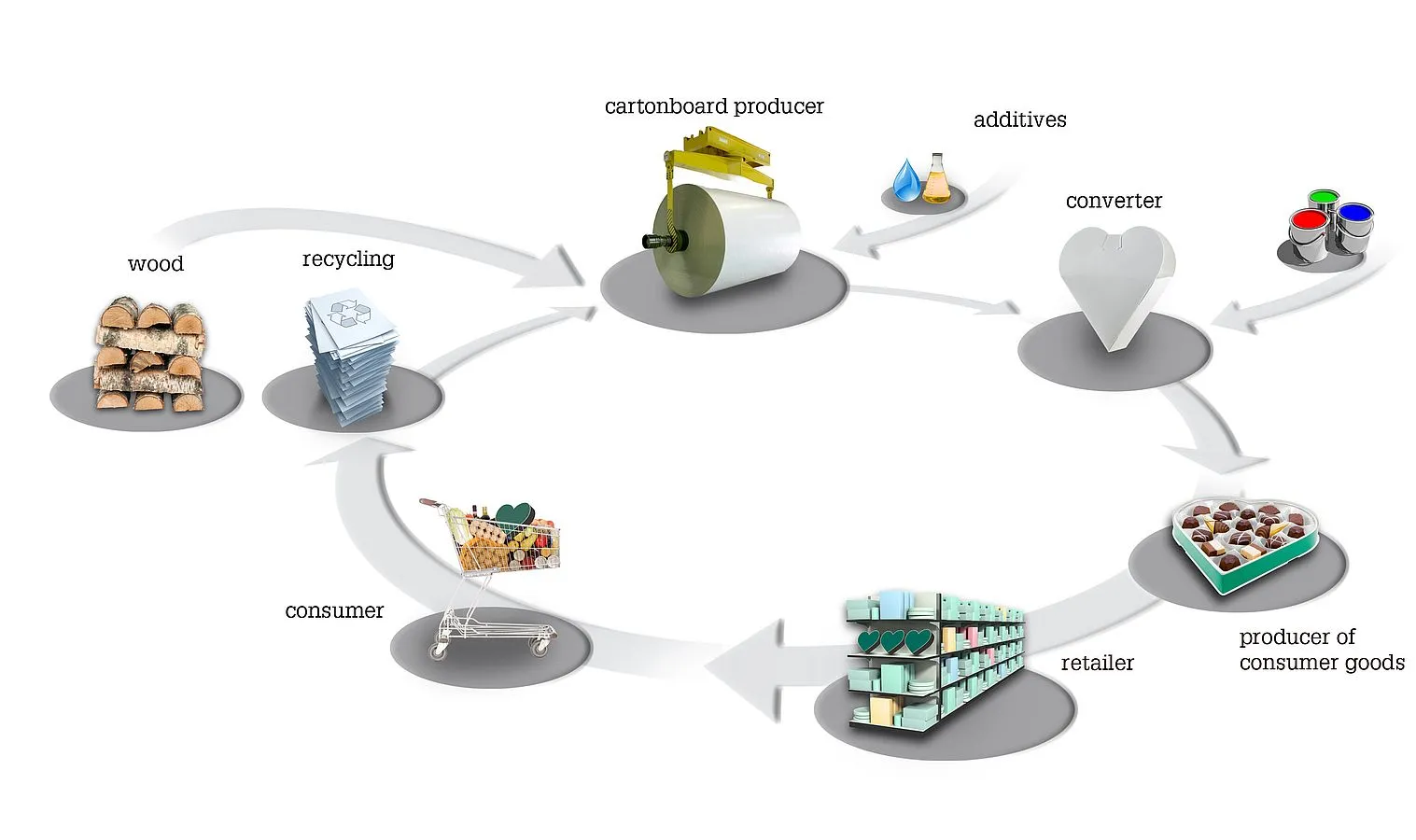

CARTONBOARD: A TRULY CLOSED PRODUCT CYCLE

The increasing pollution of the world’s oceans with plastic waste has now resulted in

concrete measures of consumer goods producers and retailers, as well as the EU. IKEA, for instance, is stopping the sale of plastic plates, and McDonald’s has announced that it will ban plastic straws from restaurants in the UK. The EU Commission issued a Europe-wide schedule for plastics in 2018 which partially bans them, reduces them, and demands a functioning recycling economy. The goal is that all plastic packaging that is put into circulation in the EU market is either re-usable or can be recycled cost-efficiently. As we know, there is still enormous need for action on this issue. For many applications that are currently packaged in plastic, cartonboard is the ecologically sustainable alternative. Cartonboard satisfies all sustainability principles: renewable, recyclable, biodegradable, functioning recycling economy.

- Sustainable forestry: The wood used by the Mayr-Melnhof Group (residual wood) and pulp come from sustainable forestry and are harvested and procured in accordance with current legal regulations. All of our mills are certified by international forest standards systems. For cartonboard production, we use only wood that is not suitable for other wood products (e.g. furniture and building materials). We also use wood chips, which are a residue product produced at saw mills.

- Production of cartonboard for folding cartons: In the MM Karton mills, we use virgin and recycled fibres to produce a comprehensive product portfolio of cartonboard and liner qualities. The energy-efficient production at MM Karton is already a clear competitive advantage.

- Production and use of folding cartons: Folding carton producers (converters) convert our cartonboard and liner into packaging that protects products along the supply chain and advertises them sustainably at the point of sale.

- Recycling: Used packaging is collected, sorted, and returned to the cartonboard production process for recycling. MM Karton obtains recovered paper exclusively from proven sources in European urban centres. Cartonboard can go through the cycle of production and re-use several times (= material recycling). Fibres can be recycled almost unlimited.

- Energetic recovery: Once material recycling is no longer possible (fibres are washed out), energetic recovery is the last step in the life cycle. In energetic recovery, unusable raw materials are turned into an energy source and used for producing energy – in the form of heat or electricity. We either use the produced energy in our own production processes, or it is added to the energy supply for nearby residences.

EU Plastics Strategy

The EU Commission has issued its first European strategy to define how plastics are to be handled in the EU in the future. The following measures are defined in this Plastics Strategy:

- Packaging manufacturers are obliged to consider requirements regarding recycling or re-use starting with the design phase of their products (extended manufacturer responsibility).

- Certain plastic products (like plastic plates) must be replaced with sustainable solutions.

- By 2030, all plastic packaging that is put into circulation in the EU market must be re-usable or cost-efficiently recyclable.

- By 2030, more than half of plastic waste produced in Europe is to be recycled.

- Principally: Production of plastic waste and pollution must be reduced.

MM Karton has the right products for replacing many plastic packaging concepts with environmentally-friendly cartonboard and liner alternatives.