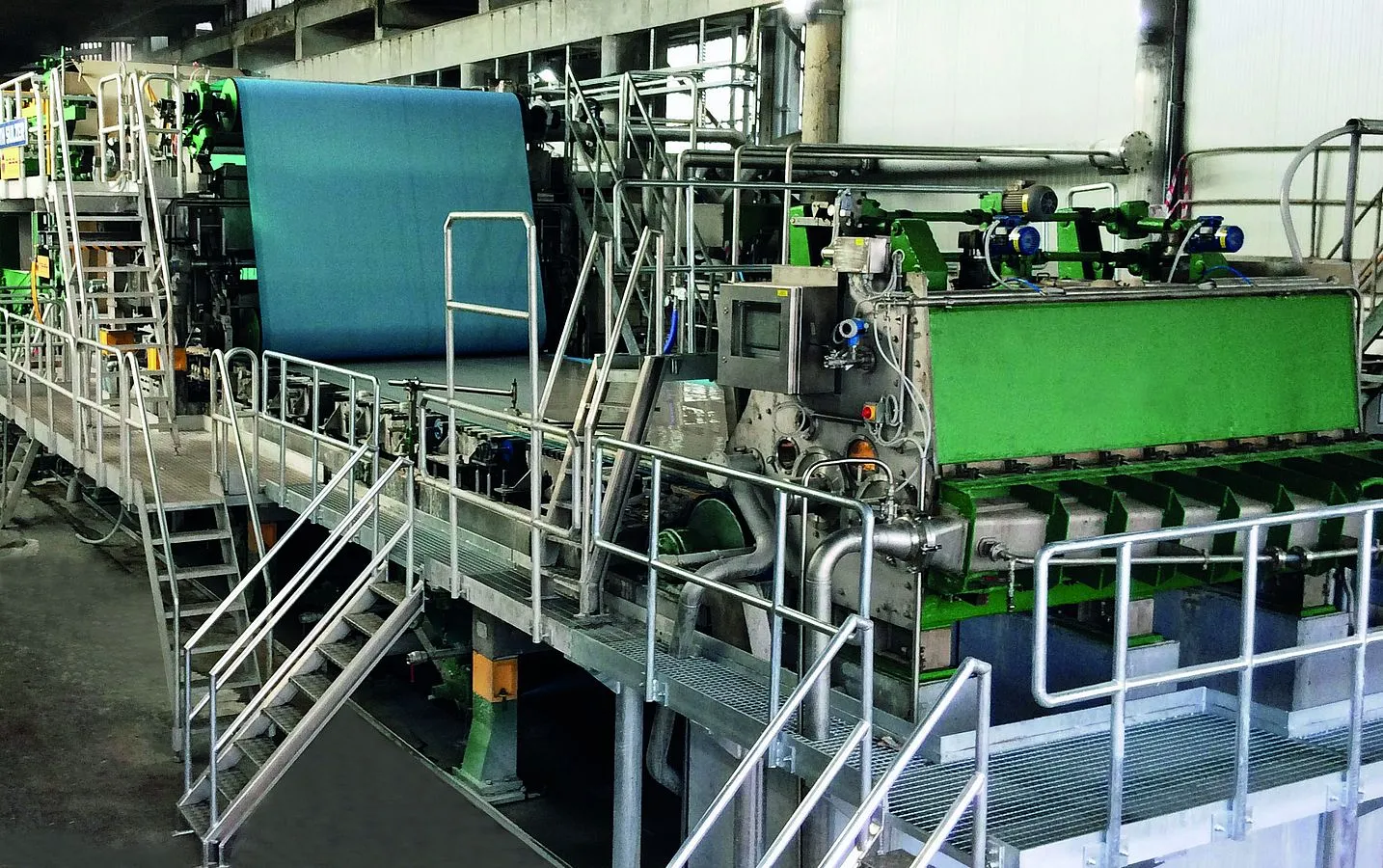

Modernisation of the BM2 wet end in the Kolicevo mill

Successful conversion of board machine 2 (BM2) at the MMK mill Kolicevo, Slovenia –

for the benefit of product quality, productivity, and the environment.

Increased efficiency BM2

In March 2016, the conversion of the wet end of the BM2 into a state-of-the-art 3-layer Fourdrinier machine was successfully completed on schedule. Additional investments were related to the renewal of vacuum systems and multiple drive units that enable a higher speed and thus improve the productivity of BM2 and work even more energy-efficiently.

Supply security during conversion phase

Through proactive advance production of standard grades in high demand, it was possible to guarantee the customary highest supply security during the conversion phase. Thanks to excellent planning, full production started again after only two weeks of rebuilt downtime.

New superior quality and extended portfolio

Most importantly: The results are demonstrated impressively in the new, strong cartonboard quality Excellent Top™ Kraft as well as a constant stable surface and an optimised stiffness ratio (L&W) of existing qualities. Our GT2 cartonboard quality Belpak™, highly valued for pharmaceutical and hygiene products, stands out more than ever with excellent stiffness values. At the same grammage and caliper, Belpak™ now offers impressive 5-10 % higher strength values.

Thanks to the conversion, the BM2 in Kolicevo is now upgraded to the latest technological standards and conquers new market segments with improved quality.