Some Like It Hot

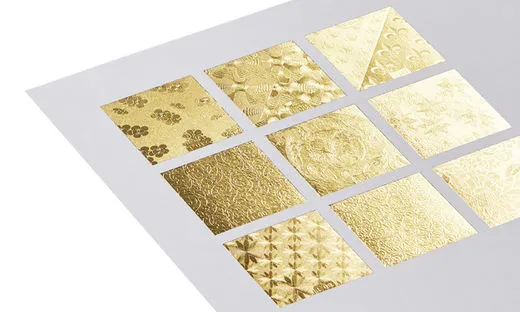

Andrew Heinzius from MM Packaging explains how hot foil stamping is applied to paper.

“Well, nobody’s perfect,” Osgood Fielding tells the lively Daphne at the end of the classic film “Some Like It Hot“, when she removes her perky wig to reveal to her suitor that she’s actually a man and that she’s been duping him all along. Andreas Heinzius, Divisional Technical Hot Foil Coordinator at MM Packaging, agrees with the famous movie quote, but when it comes to applying a hot foil to cartonboard, it’s all about real perfection. “It’s a fine interplay of heat, embossing force and contact time,” explains the hot foil coordinator. And it really does get hot: a special machine presses the wafer-thin aluminum layer onto the desired area on the cartonboard at up to 250 °C. The plastic film carrier on which it is attached is then removed.

From chocolate to perfume

From chocolate wrappers to perfume boxes, MM Packaging finishes all papers and cartonboards using this process. Incidentally, smoother, coated paper, such as the cover paper used for our cover, is best suited for this glamorous form of finishing. “By far the most glamorous effect can be achieved using this,” explains Heinzius.

Close enough to touch

Flat embossing is usually only used for large areas or very fine elements. So-called relief engraving is also very popular, which makes the foiling even more noticeable. Currently, however, there’s an increasing demand for another technology: the so-called “lens”. It can be used to simulate objects in three-dimensional relief on the hot foil. “When you look at the box, you think you can reach into it and touch the item itself,” says the film professional, fascinated.