MM BiB-Liner™ for Smurfit Kappa – good wine in new skins

Bag-in-box solutions are an innovative packaging alternative for liquids or semi-liquid foods and an attractive eye-catcher on the shelf. Smurfit Kappa Uzerche a specialist in this form of packaging – relies on our MM BiB-Liner™ for a stable and appealing presentation.

MM BiB-Liner™ – outstanding protection, excellent printability

Smurfit Kappa Uzerche has over ten years’ experience in the production of bag-in-box solutions and occupies an important position in this segment: each pack is developed especially to preserve the particular liquid inside. The wide range of closures, dispensers and handles also meet specific requirements in terms of pouring and handling. With the production of filling and packaging machines, they can offer a fully integrated solution.

When it comes to the material used for their bag-in-box packaging, the company has precise expectations. Benjamin Largenté, Administrator Offset at Smurfit Kappa Uzerche: “For bag-in-box packaging, two components in particular are decisive. On the one hand, the material must offer excellent protection during transport. On the other, the packaging must attract the attention of the customers with high quality printing. Both aspects are fulfilled by MM BiB-Liner™.“

Thanks to its unique fibre composition, MM BiB-Liner™ offers best BCT values (Box Compression Test) with the result that it provides exceptionally high package stability and protection during transport. The excellent surface of MM BiB-Liner™ offers ideal conditions for printing and finishing for individual brand and product messages thereby ensuring the best possible presentation of the products.

Bag-in-box packaging – practical, easily transportable, ecological

In the past few years, Smurfit Kappa Uzerche has also noticed a significant increase in demand for this packaging solution:“The bag-in-box market is growing – due to three good reasons: bag-in-box packaging is more practical, more easily transportable and more ecological than glass bottles“ says Benjamin Largenté. The big advantage of the bag-in-box system in comparison to bottling is the extended shelf life of products: Since no air comes into contact with the liquid after opening, consumers can store the contents for up to six weeks. Bag-in-box solutions are highly efficient during transport: the packaging is delivered flat.

This reduces storage space and transport costs. This means a “high product volume“ can be handled with a “small transport volume“. This form of packaging is environmentally sustainable, has a significantly lower carbon footprint than plastic bottles and has also an advantage over glass.*

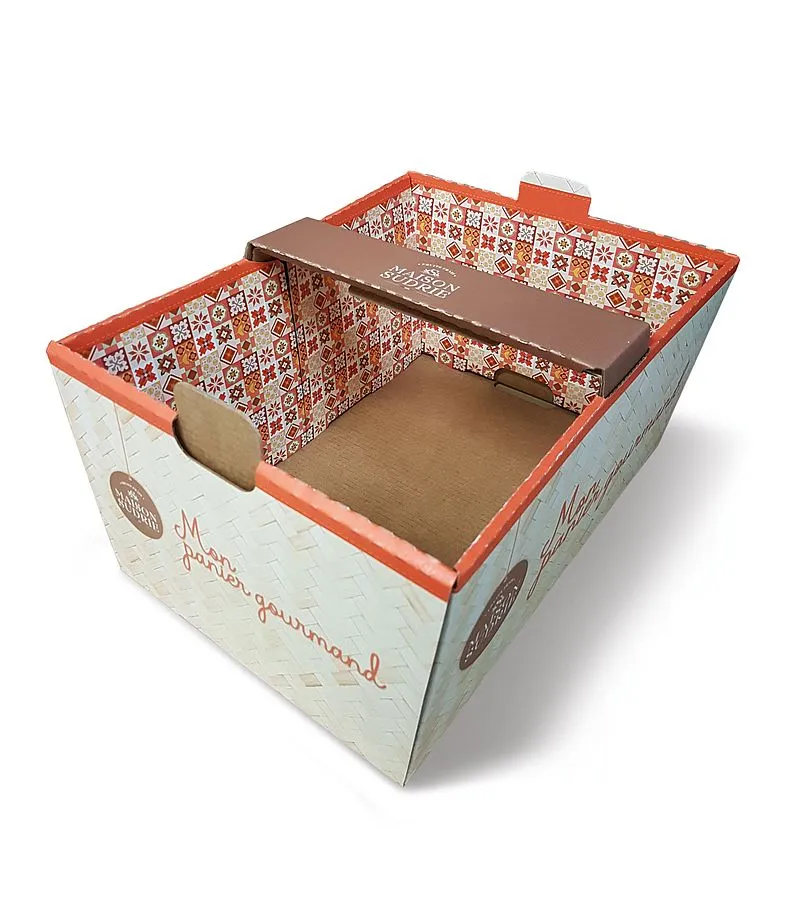

MM BiB-Liner™ was developed especially for bag-in-box applications but is being used for other purposes such as fruit and vegetable baskets, gift boxes or premium packaging for spirits. Offset printing is one of the pillars of Smurfit Kappa Uzerche who saw in MM BiB-Liner™ a replacement for kraftliner paper to achieve low grammage. Thanks to the close cooperation of Smurfit Kappa Uzerche and MM Karton, tailor-made packaging solutions for consumers will be developed – now and in the future.

*see also www.smurfitkappa.com

Interested? Datasheet and Samples can be found here:

MM BiB-Liner™ / LINER

PRODUCT CATALOGUE