Customers Count on MM Group to Support Ambitious Sustainability Goals

Business Breakfast Provides Forum to Discuss Corporate Fitness for the European Regulations Governing Packaging and Forestry

13 March, Vienna – Nearly 40 customers visited MM Group’s Vienna-based packaging plant, MM Premium for a business breakfast where they grew more connected with the MM Premium team, MM Group sustainability experts, and with each other. The program included two keynote talks on EU regulations affecting fibre-based packaging and a guided tour of the plant’s Packaging Development Center and production lines.

The keynote talks focused on the European Union Deforestation Regulation (EUDR) and the Packaging and Packaging Waste Regulation (PPWR). As early as end of 2025 for EUDR and latest by 2030 for PPWR, companies will need to have implementable compliance strategies in place. Business Breakfast attendees indicated different levels of readiness – with some companies already implementing strategy, while others were still finalizing how they would approach the regulations. The speakers offered deeper insights into how customers’ packaging spend might further their sustainability agenda while continuing to deliver expected benefits for their product brands like shelf appeal and customer experience.

Two recent MM Premium investments were highlights of the production facility tour. First, tour guide and Works Council Chairman Gerhard Novotny presented the new digital plotter. The “Leonardo Team” – MM Premium packaging designers – uses the plotter to walk customers through the entire packaging development process, from creating artwork through simulated finishing effects to the construction of fully realized packaging prototypes. Next they witnessed the new Carton Cavity System in action – producing cartonboard cavity inserts that reduce packaging plastic by replacing plastic trays.

Event organiser, MM Premium Deputy Head of Sales Hannes Köck, explained what motivated the customer-engagement event: “Packaging is experiencing a rare moment where regulation, innovation, and sustainability can align as value-adding business drivers. By delivering packaging innovations that can push recycling rates higher while maintaining performance equivalent to traditional packaging, we help future-proof customers against the commercial downsides of regulation in a way that leads to shared success for them and us.”

The path to European Union Deforestation Regulation (EUDR) compliance

EUDR has been on the books since June 2023 and will take legal force on December 30, 2025. In the fibre-based packaging value chain, companies that are affected by EUDR are those that produce virgin-fibre paper and cartonboard, recycled paper and cartonboard with any percentage of virgin material, as well as packaging using any percentage of virgin fibres – which means most fibre-based packaging.

By end of 2025, affected companies selling into the EU market must be able to document that their products do not contribute to deforestation and are produced in compliance with all applicable law. To do so, they must collect data, conduct due diligence on the supply chain, and submit statements – using the EU platform TRACES – that confirm to the appropriate authorities EUDR compliance. Each statement receives a EUDR reference and verification number, which companies also communicate to customers in scope of EUDR.

MM Head of Group Product Safety & Quality Sigrid Gerold explained to customers how EUDR might affect them differently, depending on their position on the value chain: “Most MM Packaging customers will not be affected by EUDR because packaging that is put on the market with products inside – and is used solely to support, protect or carry those products – is not subject to EUDR. MM Board & Paper customers, on the other hand, will be affected because many of them are packaging converters. Our people at MM Board & Paper therefore must be able to supply necessary documentation proving EUDR compliance.”

About one third of the attendees reported having accounted for EUDR in their business strategies. Many customers thus gained new insights into how partnering with an integrated packaging supplier like MM could deliver both cost- and time-savings enroute to becoming EUDR-compliant. MM Board & Paper and MM Packaging, connected through MM Group, have experience and expertise in ensuring sustainable and compliant fibre sourcing and fulfilling EUDR-relevant requirements. Through knowledge sharing, MM Group can therefore help industry partners develop more responsible sourcing practices for fibre procurement.

The Packaging and Packaging Waste Regulation (PPWR) – A Still-Evolving regulatory Landscape

When buying packaging, what gives customers peace of mind? Most attendees agreed: A partner who can help their brands grow more sustainable, while still delivering expected functionality and aesthetics. They need someone who can help navigate the implications of PPWR – especially while the regulation’s geography is still being mapped.

Many attendees work for food brands. Here in particular, they are looking for expert partners who can find the often elusive overlap between packaging that is fit for purpose and that at the same conforms with PPWR. The associated Annex V – which covers single-use plastics in packaging and will first be defined as of 2027 – presents additional complexity.

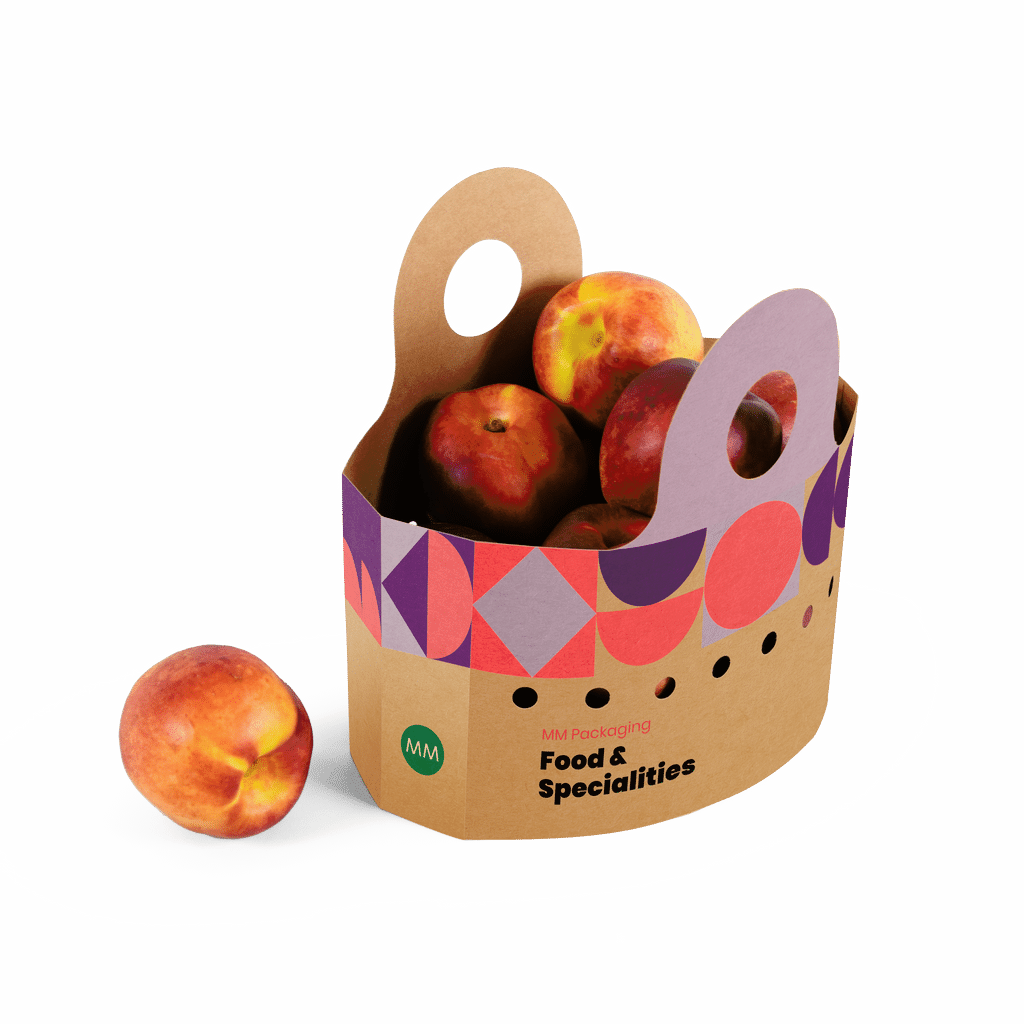

“We can work through various options together and decide what meets your requirements list,” Markus Müller, MM Group Sustainability Regulatory Expert, explained to Business Breakfast guests. “For products like fresh fruits and vegetables, mono-material trays or punnets will do the job. For frozen foods, you’ll need barrier properties. Here we can talk about a few options that will keep you compliant with PPWR and Annex V.”

If packaging uses polymeric material amounting to five percent or less of total packaging weight, this is still considered mono-material packaging. If however the product requires greater protection, then packaging engineers can design solutions where cartonboard and plastic are manually separable in practice. Such packaging would also qualify as PPWR compliant if, by 2030, up to 35% of the plastic used is recycled content. The requirement for recycled plastic will climb to 65% in 2040.

Customer Takeaways

Attendees used the opportunity to sound out the Leonardo Team on the future of packaging design for their brands over a catered buffet offering Austrian specialties. “The ability to see and touch packaging that looks exactly like it will on shelves before it goes into mass production was clearly a big draw, “ said MM Premium Head of Sales Andrea Wagner, “The chance to ‘try before you buy’ leads to happier customers and stronger relationships.”

The sustainability experts, Gerold and Müller, were also at the centre of many follow-up discussions. One topic that drew larges circles of attendees was how packaging solutions would be charged with Extended Producer Responsibility (EPR) fees. Fibre-based packaging solutions carry significantly lower fees than plastic solutions in most EU geographies – but attendees were surprised to learn that, even among fibre-based options, there is significant flexibility in cost management.

“It was an enriching experience to have sustainability experts, packaging engineers, and commercial people together in the same conversation about making packaging more sustainable and compliant with EU regulations,” said guest Juliette Berthier, Product Manager Packaging Solutions for Kwizda Agro. “Best practice sharing is clearly a priority for MM, and it helps a lot that they are actively sharing their knowhow with their industry partners.”