Fibre-based Packaging Producers Seek Clarity on Single-Use Plastic Packaging (SUP) Directive

The European Union’s SUP Directive May Pose Unintended Challenges for Non-Plastic Packaging.

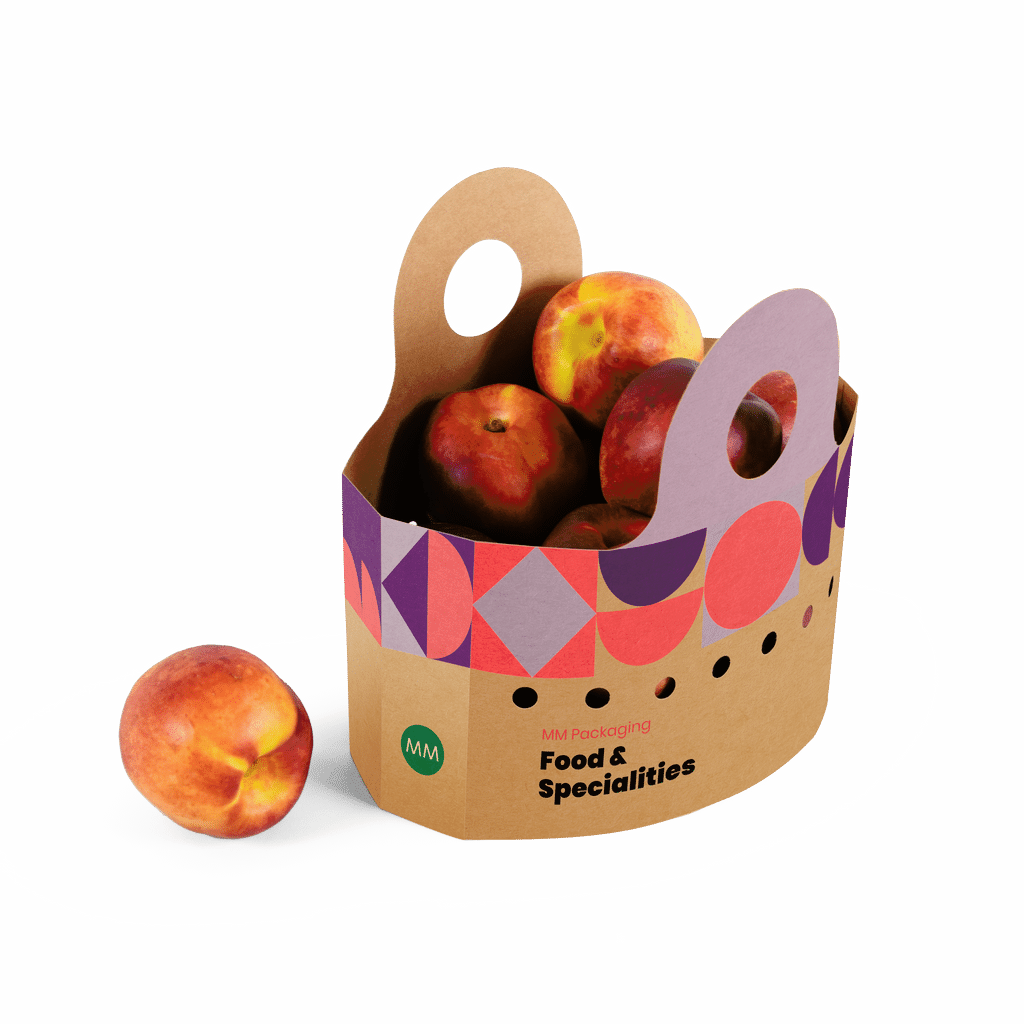

Fibre-based packaging manufacturers are unclear about how the European Union’s Single Use Plastic (SUP) Directive, adopted in 2019, will impact their business. As it applies to specific measures for minimizing litter from single-use plastic and “plastic”-containing packaging, the Directive has taken effect through national legislation. Still unclear is how the directive applies to fibre-based packaging that uses small amounts of plastic as a protective layer for perishable items. For example, cartonboard cups incorporate an internal layer to keep liquid products from seeping through the cartonboard; and fibre-based food containers often include a plastic barrier to protect the food from oxygen and to keep food oils from leaking through the packaging.

For now, this is only a Directive, but the paper packaging industry wants to ensure that Member States use the Directive to create reasonable and harmonised legislation that does not slow its efforts to replace plastics in problematic packaging formats.

The packaging industry however does not yet have this level of clarity. “MM Group sees the Directive as a ‘work in progress,’” Vishtal explains, “I would consider this a development project. We are still unclear as to how different EU member states will apply financial instruments to single-use paper packaging that includes a small percentage of plastic. Once we know this, we can pool our experience and define best practices across the geographies where we do business.” For now, MM Group understands how its portfolio aligns with the Directive in countries enforcing it.

Vishtal says this is particularly important for a company like MM Group, which manufactures packaging materials in several countries: “What we need above all is a targeted harmonisation of the approaches to introducing SUPD-related fees in different countries. However, instead of providing a blanket approach, the Directive allowed some member states to institute sensible interpretations that do not harm market operators. We hope that during upcoming revisions to the Directive, the result will be a unified approach across Europe. This will help a multinational company like MM.” Vishtal is confident that member states will begin the process by 2028 at the latest.

From today’s perspective, businesses confront several questions that need answers before the SUP Directive can be given a harmonised interpretation.

What is single-use packaging?

Although the SUP Directive was written to focus specifically on packaging that is used and immediately discarded, it can still apply to larger packaging formats in a counter-intuitive fashion. Who is defining what quantity of food or beverage is consumed in a “single use” and what quantity is large enough so that packaging needs to accommodate multiple uses – whether at home or on the go?

What is a plastic product?

According to the Directive, even a small amount of plastic makes a product a plastic product, even if the plastic components bring needed functionality to the packaging and the vast majority of the product is made from fibre-based raw materials.

The Packaging and Packaging Waste Regulation (PPWR) can offer useful guidelines here as well. PPWR limits plastic to 5% of mass in its definition of non-composite products, however SUPD still prevails as “lex specialis” for the formats it specifically defines.

A precisely defined threshold is however not without its own potential pitfalls. “If plastic were allowed to be, say, 10% and the rest was wood-fibre-based, one way to solve the problem would be to increase the amount of fibre in packaging, which would only lead to over-packaging,” says Vishtal. He says the directive should instead offer guidelines for adopting and using recyclable materials that won’t end up as trash. MM’s innovation agenda aims to bring functional and recyclable materials to market – and the Directive could help drive this agenda with clearer, more unified guidelines.

What is the turtle logo telling us?

The SUP Directive requires single-use products containing plastic to carry the “turtle logo”, which in Finland is printed on all single-use cartonboard cups, for example. This is because the Directive defines their coating as plastic.

Vishtal believes that the purpose of the label is to raise awareness of the harmfulness of plastic waste. But the problem is that a growing number of local and global labels are communicating environmental dos and don’ts in an uncoordinated manner. “Consumers may not understand the turtle label’s instructions,” says Vishtal. “Is it saying: ‘Turtles die as a result of this packaging’? Or is it saying, ‘Be kind to turtles and recycle’?”

How might the Directive better account for the packaging industry’s efforts?

EU projects generally do not sufficiently account for the effort behind building collection and recycling systems. However, the packaging industry is investing heavily in such systems. 4evergreen is a consortium of 110 companies from the whole life cycle of fibre-based packaging – from forestry to products, designers, and retailers to recyclers. The consortium has set itself the goal of recycling 90% of the products in its scope by 2030, up from the current 82.5% recycling rate for paper and board packaging in the European Union.

Takeaways

Since the mid-1990s, when Europe began introducing extended producer responsibility (EPR) programs, the European packaging industry has been accelerating toward more sustainable business models. “At MM Group, the idea ‘Think next’ guides our decision making,” explains Vishtal, “’Think next’ means two things: One, forecasting the challenges that might slow our business from becoming more circular, and two, thinking of the next solutions for overcoming these obstacles.”

Collaboration between packaging producers and EU experts on harmonising the SUP Directive’s definitions of “single use” and “plastic packaging” could lead to a win-win scenario. The EU would gain reliable guidelines for incrementally reducing the amount of plastic that is discarded after a single use, and the packaging companies could develop strategies for reducing plastic in packaging, confident in their strategies’ long-term viability.