MM Board & Paper offers partners unbiased view on virgin and recycled cartonboard

Technical Product Services Expert and packaging converter weigh fibre options and define key decision criteria

When MM Board & Paper’s Technical Product Services (TPS) Manager Michael Zelingr visited Cosal, an MM merchant, in Monterrey, Mexico—the aim was more than a routine technical exchange. The objective was to navigate the nuances of the fibre landscape and discover how Cosal could reach its goal of delivering functionally impeccable packaging raw material (board), while helping customers realise their ESG goals.

Cosal’s sales team and Zelingr worked closely together to examine current board usage and evolving market demands. The exchange reflected a true partnership. Cosal, known for its deep understanding of the board market and its strong local presence, welcomed the opportunity to better understand the full range of cartonboard options—especially in light of shifting regulations, heightened environmental expectations on FMCG brands, and changing end-user preferences.

Zelingr offered a clear technical look at key substrates—including a comparative analysis of local recycled grades and MM Board & Paper’s own WLC (white lined chipboard) recycled board range. This sparked dialogue around board structure, sheeting, and performance under different converting and end-use conditions.

The material-agnostic approach that Zelingr presented stood out. Rather than promoting one type of fibre over another, he emphasized that the best choice always depends on context: WLC offers printability and cost efficiency for a wide range of consumer goods, while virgin fibre FBB (folding boxboard) provides the structural integrity and reliability needed in more demanding sectors like pharma and food.

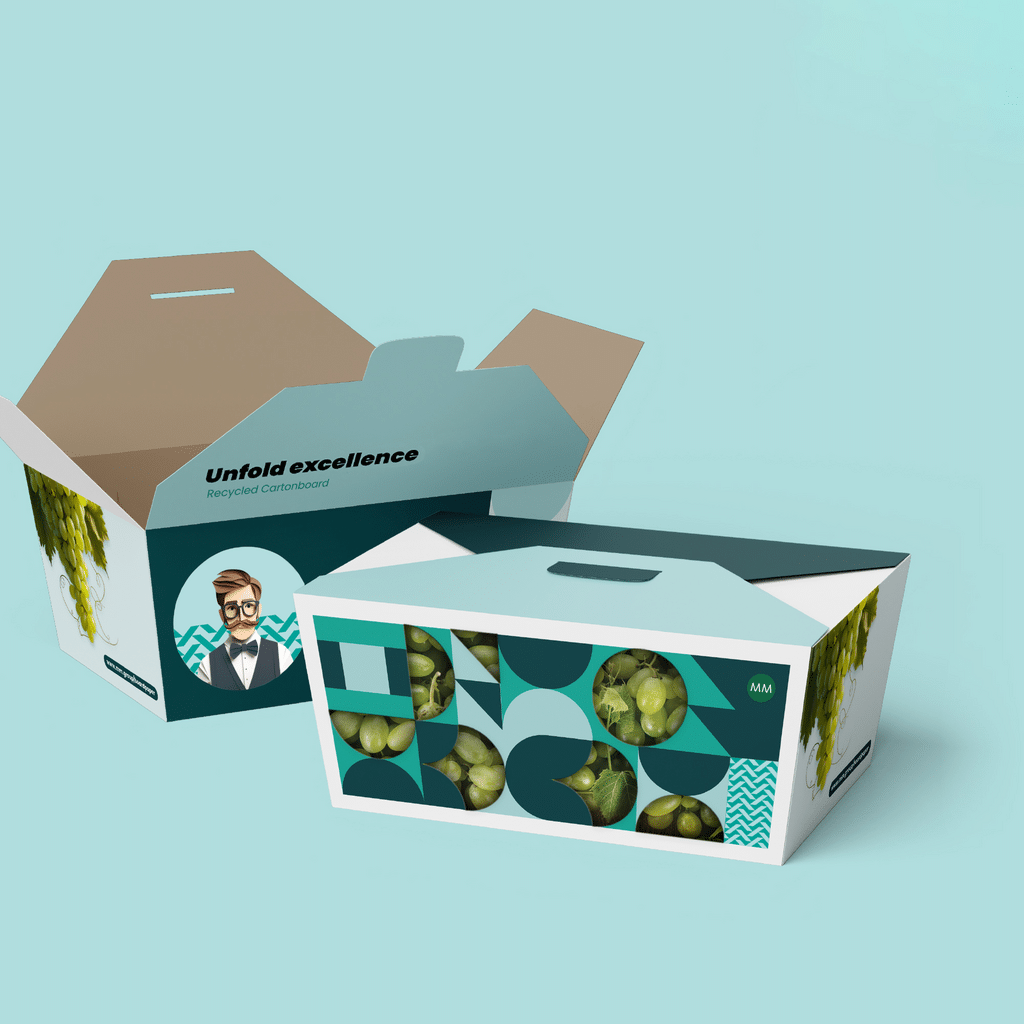

This balanced perspective resonated with Cosal’s team. While the company had already identified specific challenges – such as optimizing board stiffness and surface quality for premium applications – Zelingr’s insights offered new clarity. He demonstrated how MM’s recycled cartonboard portfolio, including products like MCB® and TOPCOLOR®, can balance performance and sustainability. This is achieved by calibrating advanced cleaning and coating processes to a wide range of applications once thought to require virgin fibre cartonboard.

Still, for cold-chain packaging or applications where print precision and braille coding is needed, the long-fibre structure of premium virgin cartonboard like ALASKA® STRONG remains essential. These nuanced discussions enabled Cosal to consider trade-offs more precisely, empowering them to support their own customers with new expertise.

In the end, the visit reflected what makes this partnership work: MM and Cosal each bring critical expertise to the table, and together they make outcomes possible that they could not achieve individually. Through mutual learning and forward-thinking collaboration, both companies are better positioned to meet the challenges—and seize the opportunities—of today’s fast-moving packaging landscape.