Redefining energy use in packaging

On October 21, World Energy Saving Day draws attention to the critical role of energy efficiency in shaping the future of business. For professionals across the packaging industry, it highlights how every decision around packaging design, production, and supply chain has an impact on sustainability, competitiveness, and long-term resilience. By approaching energy as a strategic resource, companies can unlock innovation, optimise operations, and strengthen collaboration across the value chain.

Turning energy into a strategic advantage

In practice, energy efficiency comes to life through three key levers: technology upgrades, renewable sourcing, and circular design. Modern production technologies, optimised energy flows, and heat recovery systems boost operational performance while ensuring consistent quality. At the same time, sourcing renewable electricity enhances energy security and reduces operational emissions. Circular design supports energy reduction across the product lifecycle by using recyclable, resource-efficient materials.

MM Board & Paper applies these principles across all mills, with energy-saving measures tracked from idea to execution. Current initiatives focus on several key projects. MM Kotkamills and MM Kwidzyn are optimising process and steam network controls to reduce primary energy consumption. Waste heat recovery from boiler flue gases has been successfully implemented at MM Kwidzyn, with plans to extend it to MM Kotkamills. Outdated motors and pumps are being continuously replaced, and voluntary external energy audits were recently completed at MM Frohnleiten and will soon begin at MM Neuss.

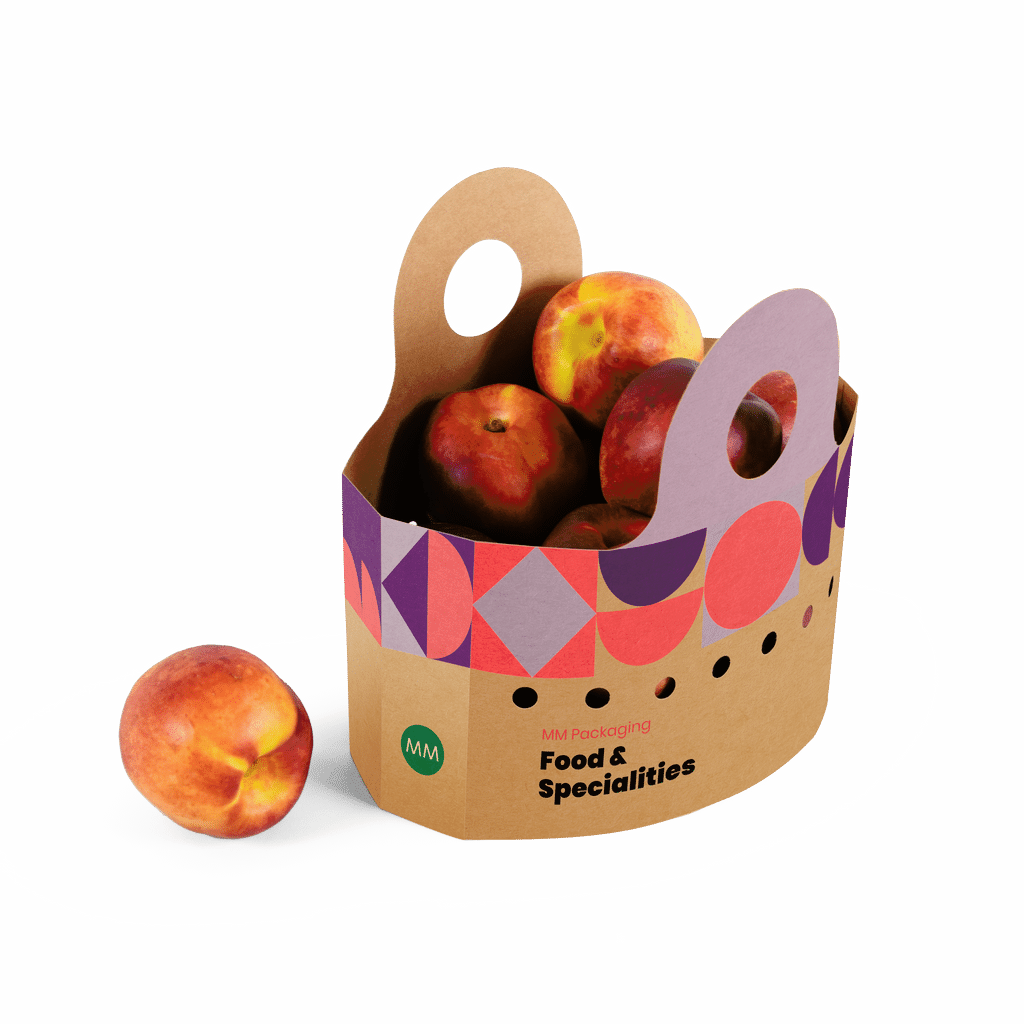

MM Packaging, on the other hand, focuses on efficient production processes, integrating renewable energy and circular materials to reduce energy intensity while delivering functional and smart solutions. Across its sites, MM Packaging is continuously improving energy efficiency by optimising production technologies, upgrading equipment, and enhancing energy management systems. MM Premium St. Hilaire in France serves as a strong example – producing all luxury beauty packaging solutions using 100% renewable energy. Similar initiatives are being rolled out across other plants to further reduce energy use, emissions, and operational costs in line with MM Group’s decarbonisation targets.

Partnering for a low-carbon future

Energy efficiency achieves its full potential through collaboration. Partnerships with suppliers, logistics providers, customers, and recycling networks optimise materials, processes, and infrastructure. Aligning operations around energy efficiency strengthens competitiveness, secures reliable supply, and supports broader sustainability targets.

World Energy Saving Day is a reminder that every action to use energy wisely compounds across the value chain. When design, production, and collaboration align around efficiency, the industry reduces energy use while uncovering new opportunities for growth and innovation.