Cutting edge – like an advanced course in cookie cutting

Die cutting is a key finishing technique in packaging production. According to Andreas Macku, this is actually a simple technique; however, you need a lot of experience to get perfect results.

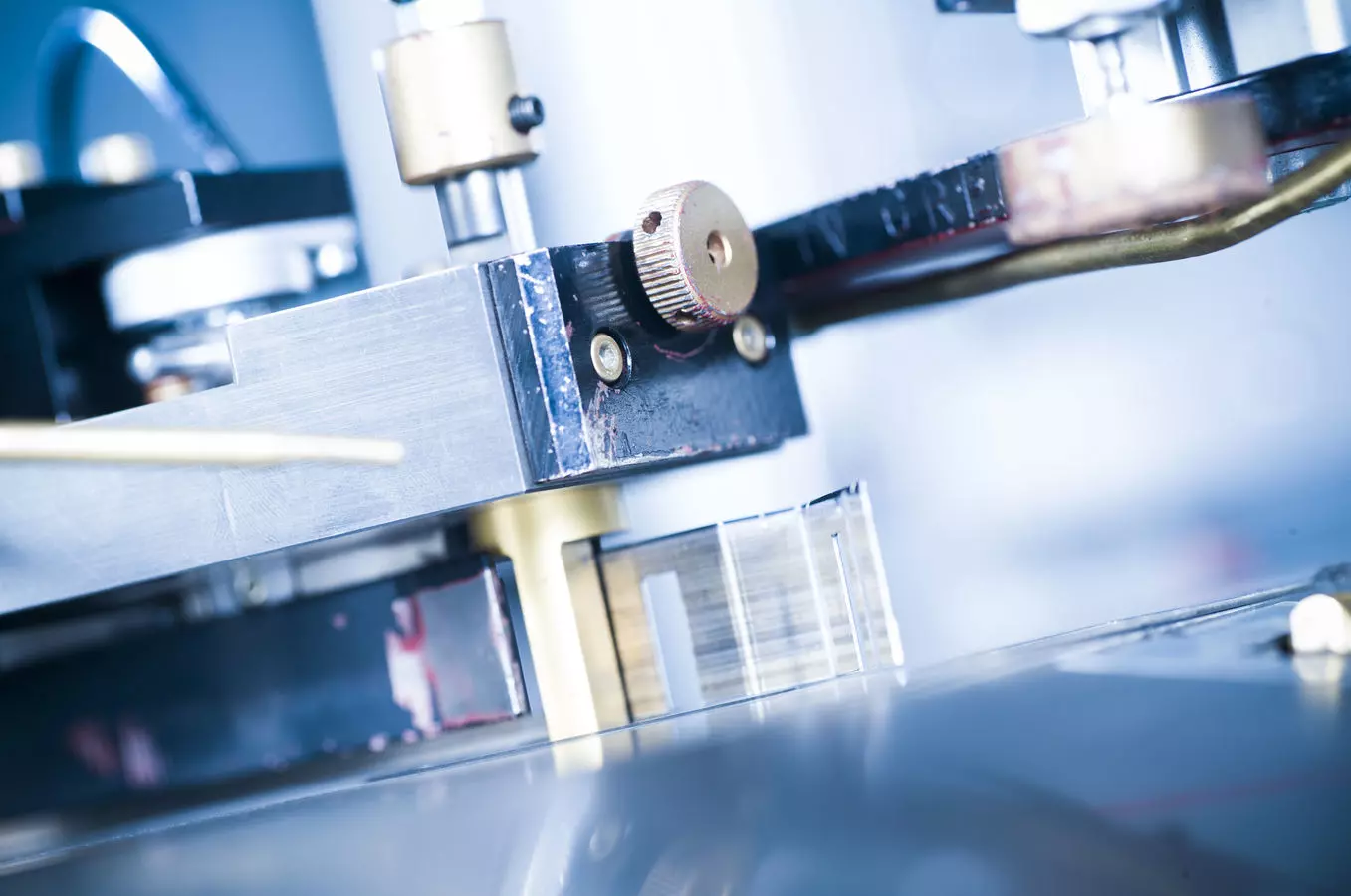

Die cutting is a key finishing technique in packaging production. It is usually performed in one process (inline) directly after printing together with the creasing operation.

“It’s like cutting cookies out of dough at Christmas time,” explains Andreas Macku, Head of Innovation at MMP. The razor-sharp edges of the customised die cutter separate the outer edges of the product from the printed sheet. To prevent the punched-out section from getting stuck in the cutter – something most of us have experienced when cutting out cookies – a rubber is placed outside the cutting lines to push away the paper. The blanks are only broken out of the punched cartonboard sheets by hand or machine during the next step. The scraps of cartonboard can be recycled.

What makes a good die cutting process?

This sounds like a simple question. “To get the best results, you need experienced professionals,” Andreas Macku continues. A lot of knowledge and skill are required, starting with the right choice of material and tool. During production, the die cutter must be set up very carefully to suit the type and thickness of the cartonboard so that the parts are cleanly separated from each other. But you also need to keep an eye on factors such as material storage methods and wear and tear on the cutting die.

What are the limitations of die cutting?

“It is not possible to cut and emboss in the same place,” Andreas Macku explains. Minimum distances are required to the creasing and cutting lines, and to deep and shallow embossing. The rounded corner of this magazine is actually cut and not die cut. “You could die cut this in theory; however, the finished magazine won’t fit through a standard stamping machine,” Andreas Macku continues.