Re*Flect: when design meets sustainability

Sustainable packaging is taking the beauty and personal care industry by storm. With this growing demand for options with a more positive environmental impact, our customers are looking for packaging solutions that don’t compromise on design and quality. The “Re*Flect” portfolio delivers a wide a range of metallic finishing effects that benefit customers through appealing packaging at the point of sale and help achieve higher cartonboard recycling rates.

Finishing effects that benefit our customers and the planet.

As the packaging industry moves towards more sustainable options, MM is leading the way. “We know that our customers are concerned about how their packaging impacts the environment, and we want to help. When it comes to combining design and sustainability we have been making big moves”, emphasises Jens Uhlmann, Innovation Director for the Business Unit Beauty and Personal Care business unit at MM Packaging. “With our Re*Flect portfolio, customers can have style, appearance and recyclable packaging at the same time.” Depending on each customers’ requirements and needs, MM helps them choose the right option from various techniques, such as varnishes, hot stamping with or without micro-embossing, cold transfer and full surface transfer-technologies.

The Truth about Hot Stamping and Cold Transfer

A frequent misconception in the industry is that hot stamping and cold transfer involve the direct application of plastic foil onto a cartonboard packaging. The reality is that the metallic pigment is transferred to the board without leaving a plastic layer on the cartonboard packaging. Re*Flect finesse provides high quality hot stamping and Re*flect charm is a proven method of cold transfer. The commonly used names for these two finishing techniques – hot foil and cold foil – are misleading, which is why MM rebranded them and added them to the Re*Flect portfolio.

In addition to the environmental benefit of not leaving plastic residue on the cartonboard, Re*Flect also offers aesthetic advantages that can surpass more traditional finishing techniques. The big benefit when using Re*Flect finesse or Re*Flect charm is, that the whiteness on the non-metallic parts are based on the board whitness, while on MET-Pet it is a shade of grey. That is making it ideal for products that require a clean and crisp appearance.

Reflecting on recycling and splitting hairs

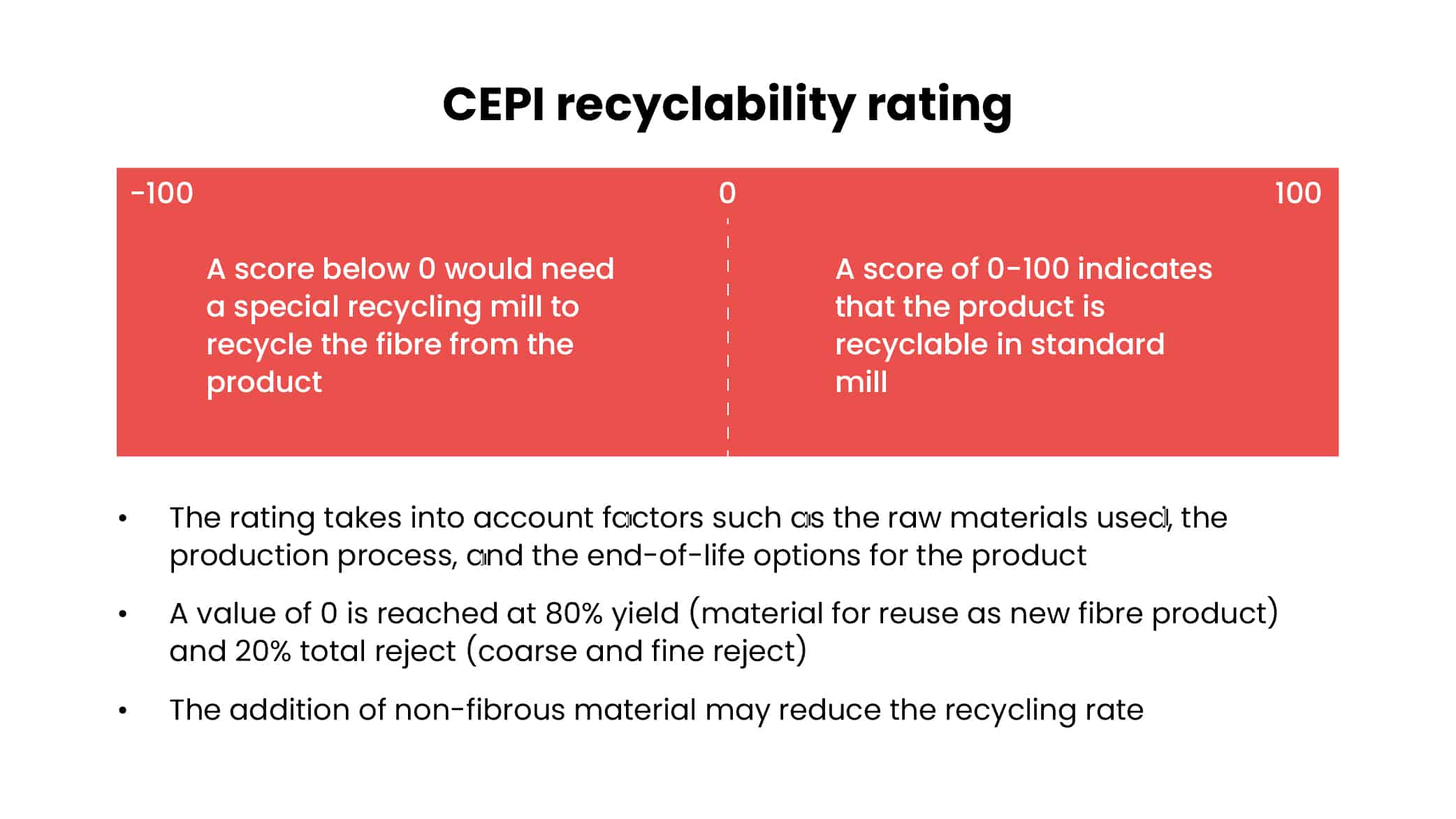

The obvious advantage of not applying plastic foil directly onto the cartonboard, is that the packaging becomes more easily sortable and recyclable. In fact, both Re*Flect finesse and Re*Flect charm can be called best in class with a CEPI recyclability rating of >80 *.

The metallic pigment that is transferred onto the cartonboard when using Re*Flect finesse or Re*Flect charm is between 0,02 µm, making it >80 times thinner than a human hair (+ max 2-4gsm adhesive). For comparison, todays MET-Pet ranks between 8-12mµ PET layer including the metallization and adhesives. The reduced amount of non-fibrous material that is added to the board with the use of Re*Flect further improves the recycling stream and also saves on material costs.

Re*Flect portfolio

With consumers group becoming more and more aware of the positive environmental impact of a functioning circular economy, many want to do their part and shop with a clear conscience.

Thinking in circles

Improved sortability and recyclability support circular economy by keeping the valuable wood fibres in the recycling loop. The more fibres are recycled, the more positive impact it creates. When using thinner metal films natural resources are also saved and less unwanted recycling process residual waste is created from plastic and metal, preventing landfill waste. Using less fossil based materials such as PET, can also have a positive impact on our customer’s products life cycle analysis (LCA) and carbon footprint. In our internal preliminary carbon footprint study of finishing methods such as reflect or MET-Pet, reflect shows a great potential to carbon footprint reduction.

The fact that Re*Flect does not combine plastic into the design will also help to navigate the new EU packaging packaging waste regulation (PPWR) with less cost from extended producer responsibility (EPR) fees. Using Re*Flect as the preferred finishing technique will help ensure alignment with the challenging directive – all this while looking gorgeous on the shelf.

A radiant collaboration from the start

We understand that our customers products are unique, and their packaging should be too. Uhlmann emphasizes the benefit of involving MM from the early design stages: With a vast range of finishing techniques available, early inclusion allows customers to get a cost-effective tailor-made solution. “Often, minor changes can have a major impact on cost and environmental impacts” says Uhlmann, “our aim is to harmonise the entire process and always find a solution that aligns with our customers’ brand values.” All of MM’s Beauty & Personal Care sites as well as most Pharma & Healthcare and Food & Speciality sites are equipped to produce Re*Flect, ensuring that customers receive consistent and reliable packaging for their products.

What the future brings

When asked what the future holds for Re*Flect Uhlmann shares exciting news: “The glossy surface known from Trans-Met applications can now be achieved by using Re*Flect radiance, thus scoring an even better recyclability rating.” Uhlmann adds: “We are continuously working on improving the sustainability aspect of existing techniques, such as their sortability, and expanding the Re*Flect portfolio at the same time.”

We want to offer the best packaging for our customers’ individual products. Contact us to find out how we can help you switch to a more sustainable and cost-effective solution with the Re*Flect portfolio.

Sortability

Sortability

When taking a closer look at sortability, using finishing such as Re*Flect might be crucial: IR systems used for sorting waste in certain countries (e.g. France) don’t always detect MET-Pet packaging as cartonboard. As a result, these packages don’t enter the recycling stream. With Re*Flect Finesse and Charm, the infrared systems have no trouble identifying a packaging as cartonboard, thus facilitating a circular economy.