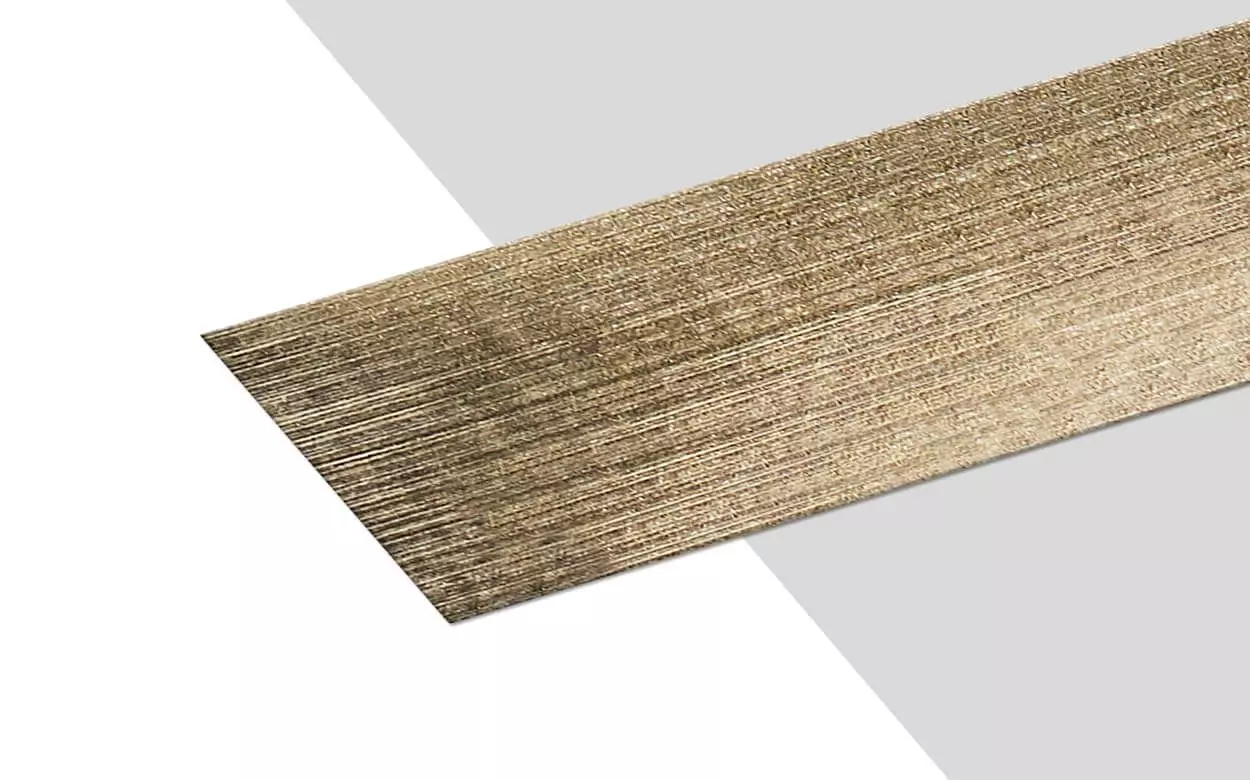

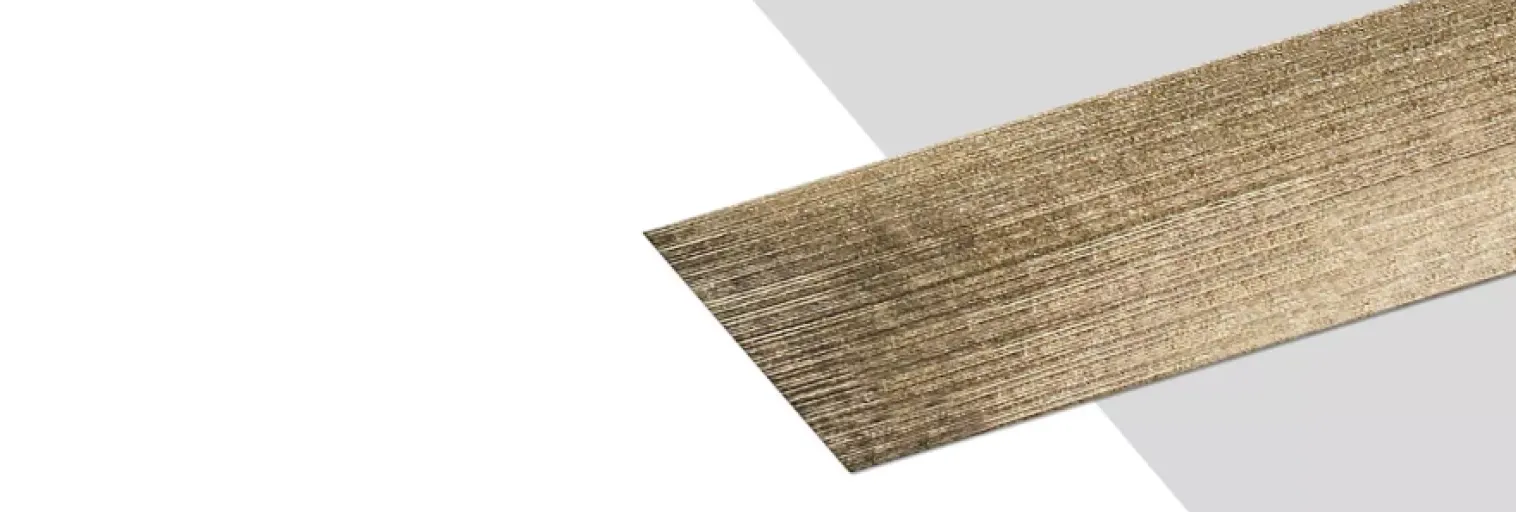

Cold Transfer

Our cold transfer effect achieved on our state-of-the-art machinery. Inline application that attracts and fascinates.

Cold Transfer

Technical Specifications

Cold Transfer

Sustainable benefits

01

Energy Efficiency

Cold transfer uses less energy compared to hot foil stamping, making it a more sustainable choice for packaging production.

02

More sustainable Materials

Cold transfer can be done on recycled or sustainable materials, supporting environmentally responsible packaging solutions.

03

No Harmful Chemicals

The process does not involve harmful chemicals or solvents, reducing the environmental impact and ensuring safer production practices.

04

Waste Reduction

Efficient application methods minimise waste, contributing to a more sustainable production process overall.

LOCATIONS