PACKAGING

Die-cutting and creasing

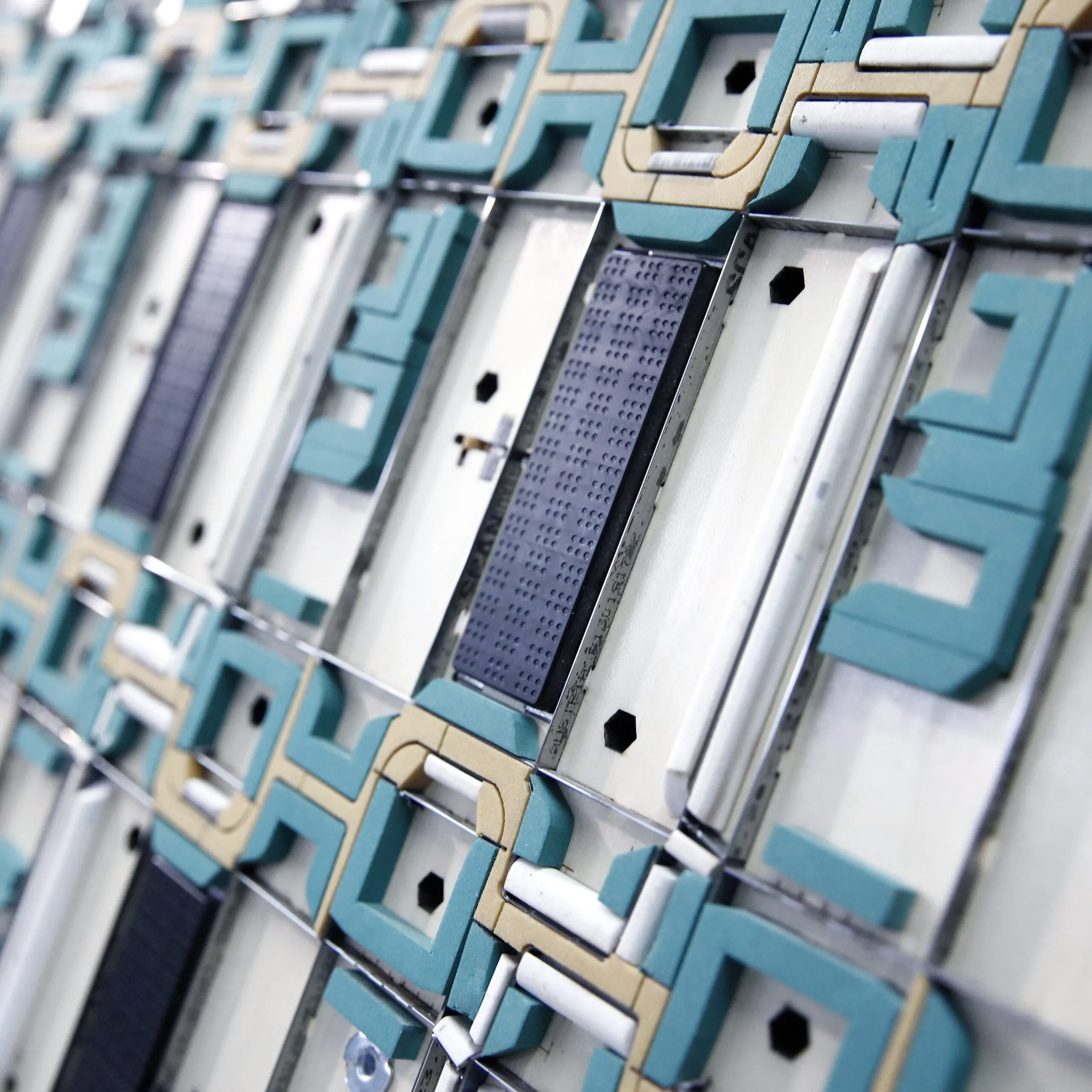

Die-cutting uses a die to cut or crease materials like paper or cardboard for custom packaging. Flatbed, rotary dies, or lasers create complex shapes and designs.

Die-cutting and creasing

Features

Die-Cutting and Creasing

Technical Specifications

Die-Cutting and Creasing

Sustainable benefits

01

Material Efficiency

Die cutting optimizes material use by precisely cutting shapes with minimal waste, contributing to more sustainable production practices.

02

Energy Efficiency

Certain die-cutting methods, like digital die cutting, consume less energy compared to traditional methods, supporting a more sustainable production.

03

Waste Reduction

Efficient die-cutting processes reduce material waste and promote recycling, aiding in sustainable manufacturing.

04

No Harmful Chemicals

The process does not involve harmful chemicals, ensuring safer production and reducing environmental impact.