Packaging

Embossing

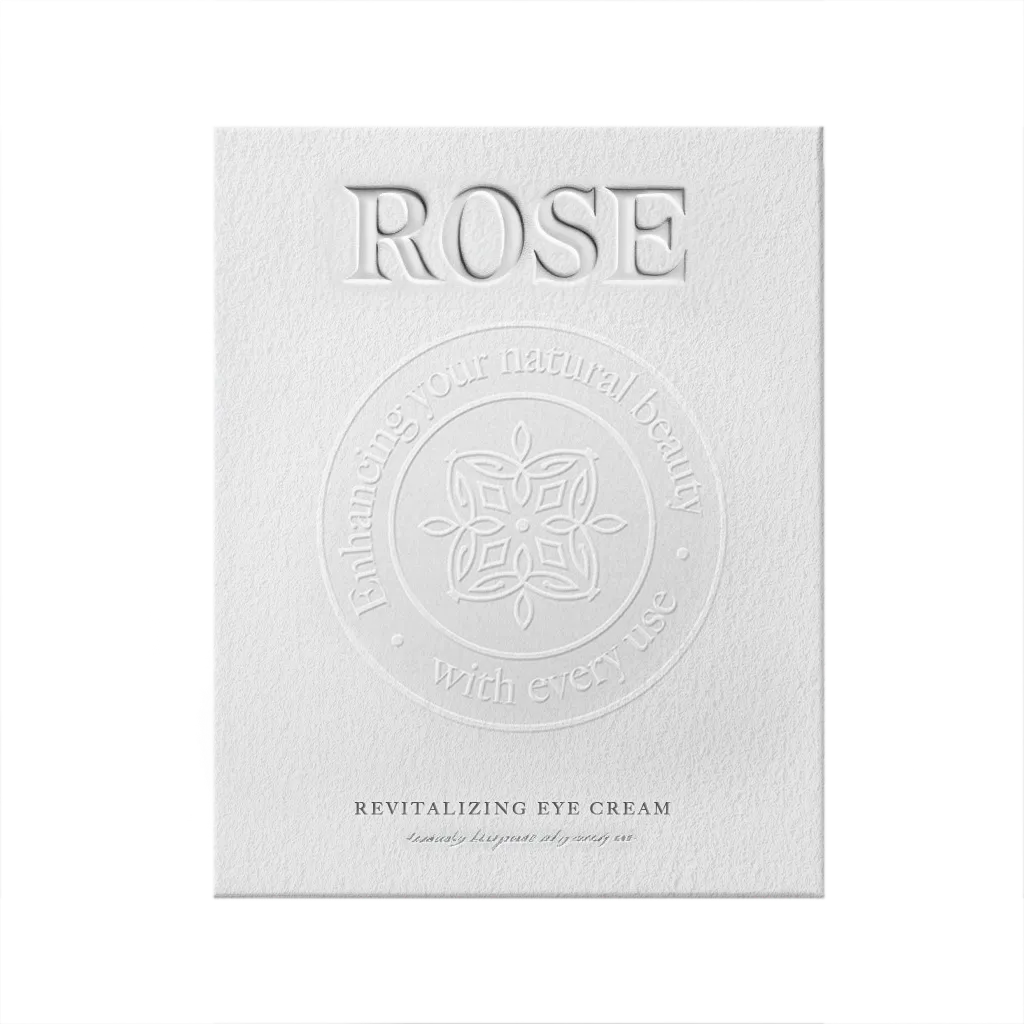

Create a tactile experience for your consumer and a 3D effect for your packaging product with the embossing and debossing technology.

Embossing

Emboss or Deboss

Embossing

Sustainable Benefits

01

No chemicals or solvents

Can be implemented without the use of harmful chemicals or solvents

02

Flexible

Can be created on nearly all kinds of carton or paper substrates