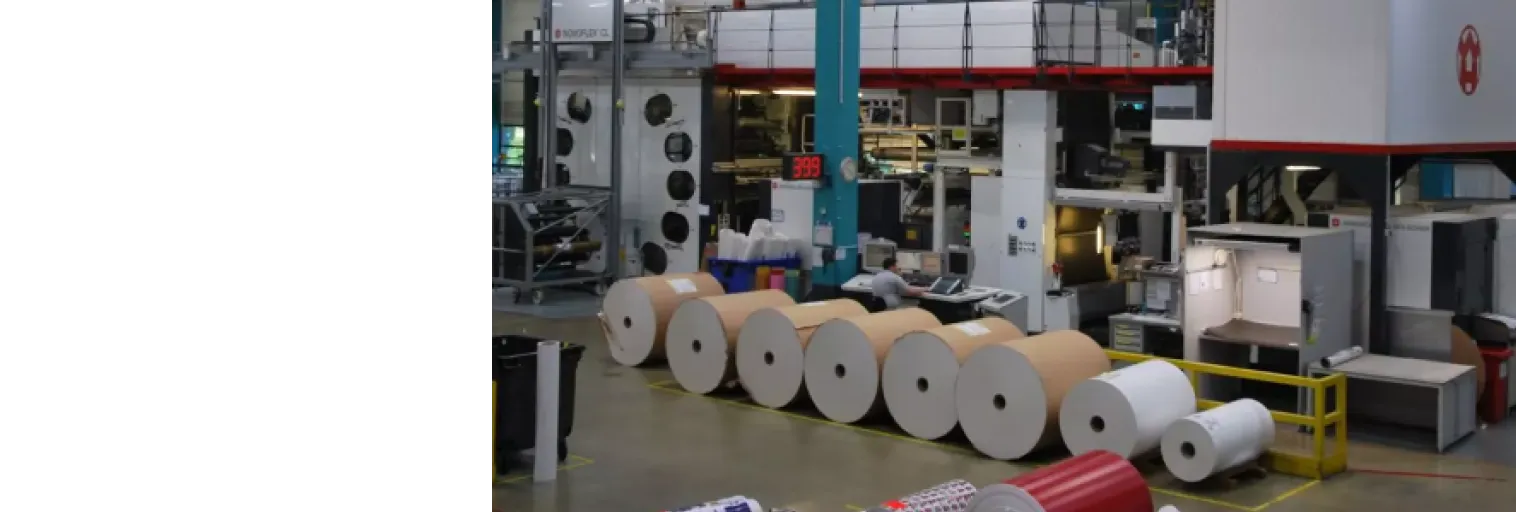

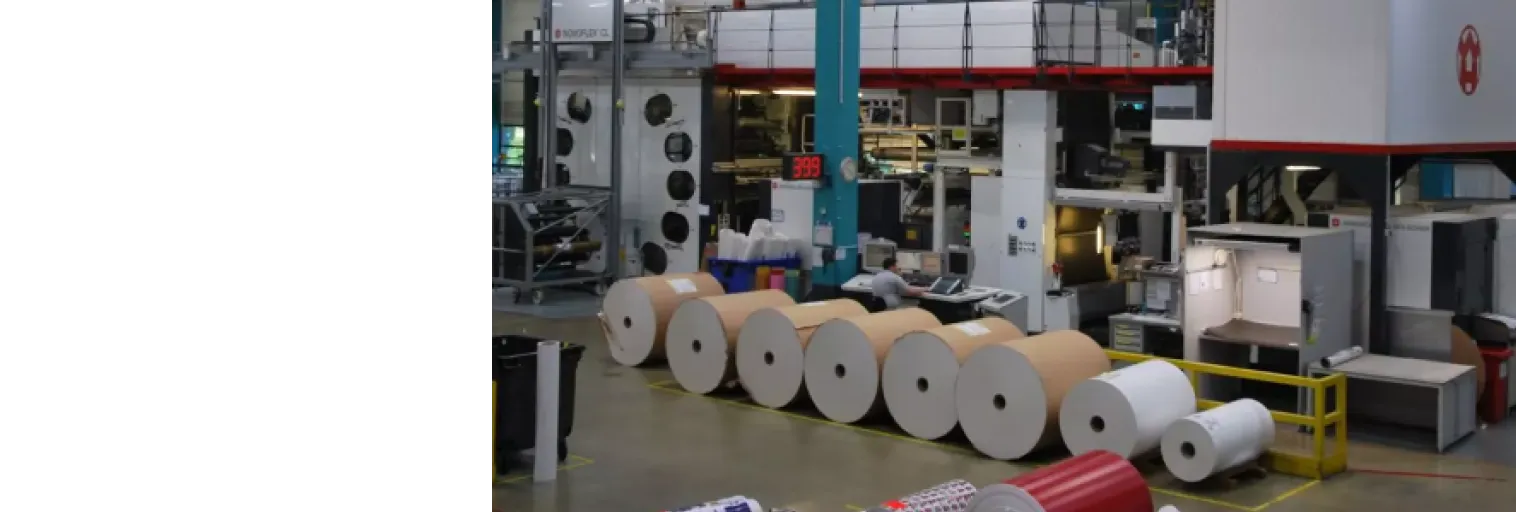

Flexo Printing

Flexo printing is a cost-effective printing technique to produce vibrant packaging materials.

LOCATIONS

Flexo printing is a cost-effective printing technique to produce vibrant packaging materials.