Confirmed by external institute: GC2 qualities from Eerbeek – the perfect choice for PE coatings

The Belgian Packaging Institute (BVI) confirms the excellent adhesion of polymer coatings (PE, polyethylene) on our virgin fibre cartonboard qualities, Silvaboard™ and Linoplex™, from our Dutch mill in Eerbeek.

Plybond strength and surface strength crucial for best possible adhesion

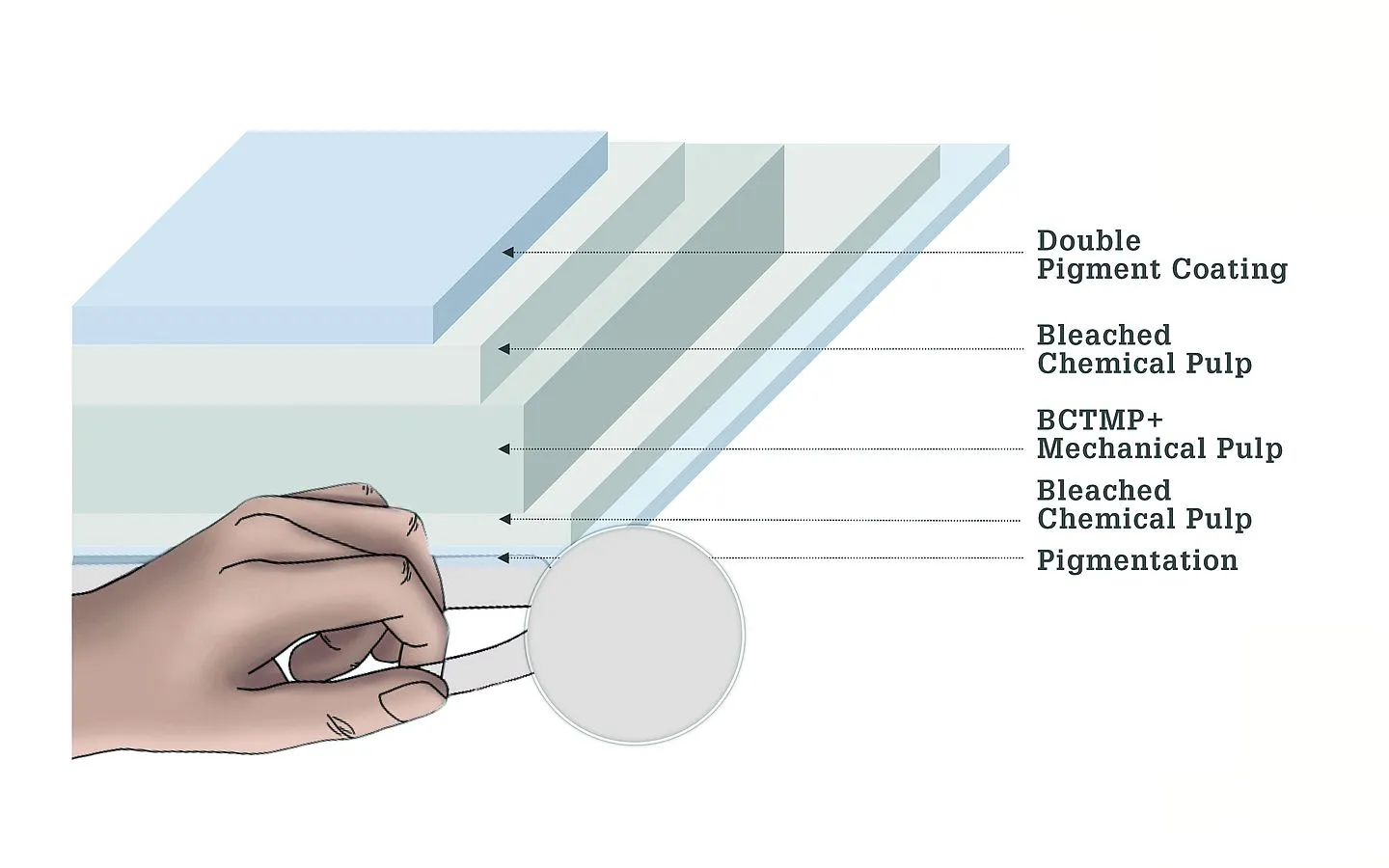

Depending on the product requirements, specific polymers (e.g. LDPE, HDPE, PP) are used in PE lamination or extrusion techniques in order to achieve a functional coating on the cartonboard and in this way to protect the packaged product from moisture or grease.

Important prerequisites for the best possible adhesion of a compound consisting of folding carton material and foil include the plybond strength of the cartonboard and its surface strength as well as optimum processing climate (23° C, 50 % humidity).

GC2 qualities from Eerbeek: excellent test results

The comprehensive comparative tests to ASTM F88, a standard testing method to determine the seal strength of flexible materials, confirm the high plybond and surface strength of Silvaboard™ and Linoplex™ as well as the perfect adhesion of the foil on the reverse side of board.

The reverse side of our cartonboard qualities is pigmented and the desired perfect adhesion of PE is therefore on the pigmentation. The quality of adhesion is verifiably comparable with grades without backside pigmentation where normally fibre tear occurs (cf. info box).

The GC2 qualities from the Eerbeek mill are therefore converters‘ first choice for packaging solutions where a PE coating is used.

Tape test – standard practice but unscientific

The so-called tape test is frequently used to test the strength of PE lamination on cartonboard and in doing so to identify possible weaknesses.

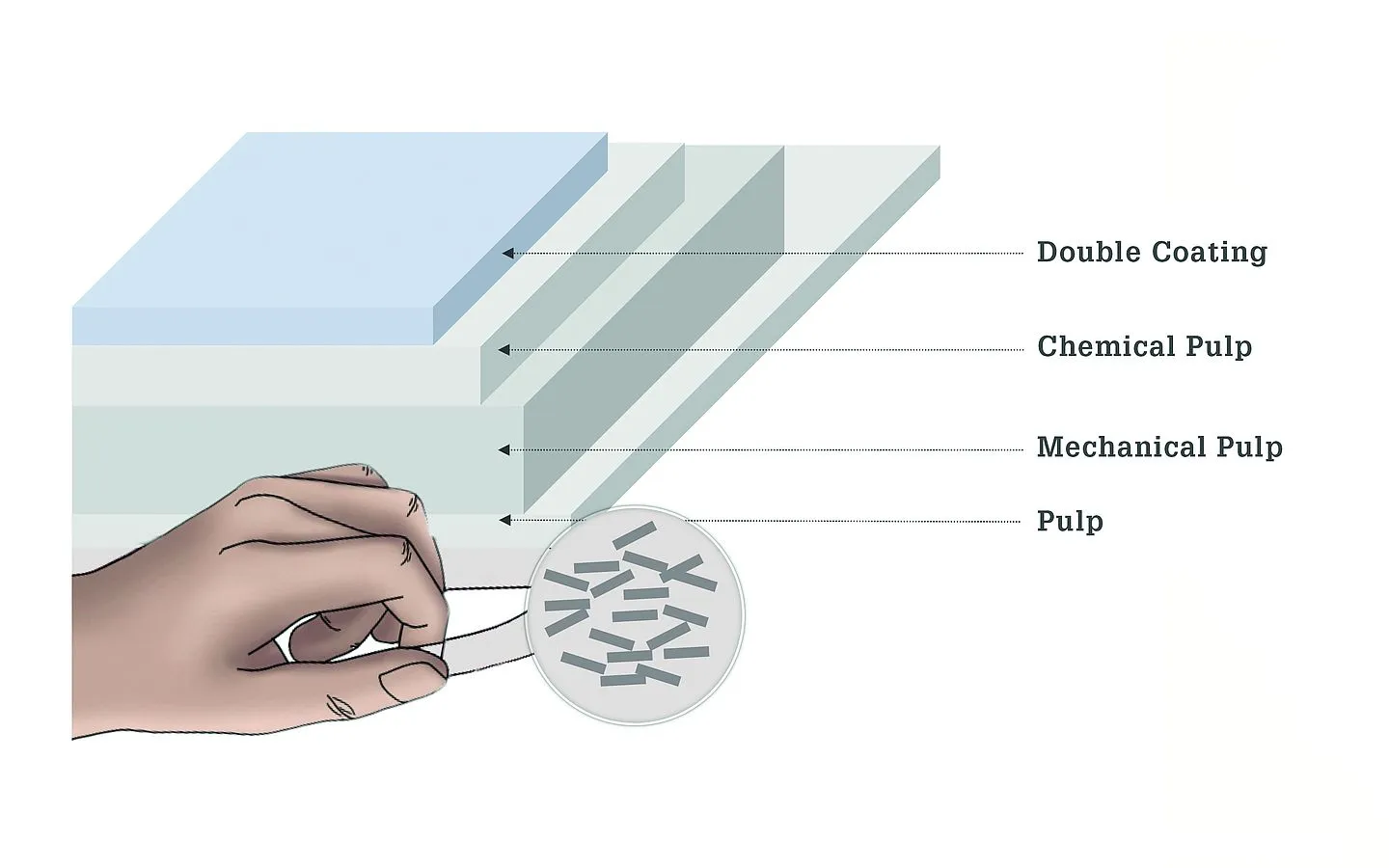

An adhesive strip approx. 10 cm in length is applied to the surface to be tested with defined pressure and then removed again with constant force. The fibres stuck to the tape are supposed to allow conclusions to be drawn on the bonding strength. A good coating leads to a complete fibre tear – as the widespread misbelief. While fibre tear will occur on the reverse of untreated cartonboard qualities, in the case of those with pigmentation on the reverse, the pigmentation will come off (cf. Fig.). The necessary force is important, not the fibre tear.