Smart materials for packaging: enhancing performance and resource efficiency

How technical service and collaboration drive more sustainable, high-quality packaging

As regulatory pressure grows and market demands intensify, packaging development is facing a new reality. The Packaging and Packaging Waste Regulation (PPWR) has raised the bar for recyclability, as well as resource and waste efficiency, pushing companies to rethink materials and processes. At the same time, supply chain resilience and production reliability remain essential to delivering high-quality packaging at scale.

Future Ready Packaging 2.0, hosted by STI Group in Lauterbach this year, brought these topics to the table. The workshop gathered experts from across the value chain – from brand owners and sustainability consultants to technical specialists and paper manufacturers – for a hands-on exchange focused on performance, lightweighting and innovation. MM Board & Paper played a key role, with Technical Product Service Managers Heinz Taubach and Roberto Gamba leading one of the interactive sessions.

Driving more sustainable packaging performance through expert technical support

The ability to develop board and cardboard packaging and other packaging supplies that are both resource efficient and fit for purpose depends heavily on material quality. While recyclability is considered essential by the industry, materials must also perform consistently across converting, filling and distribution. In the workshop, the Technical Product Service Team (TPS) demonstrated how to balance these factors based on targeted outcomes.

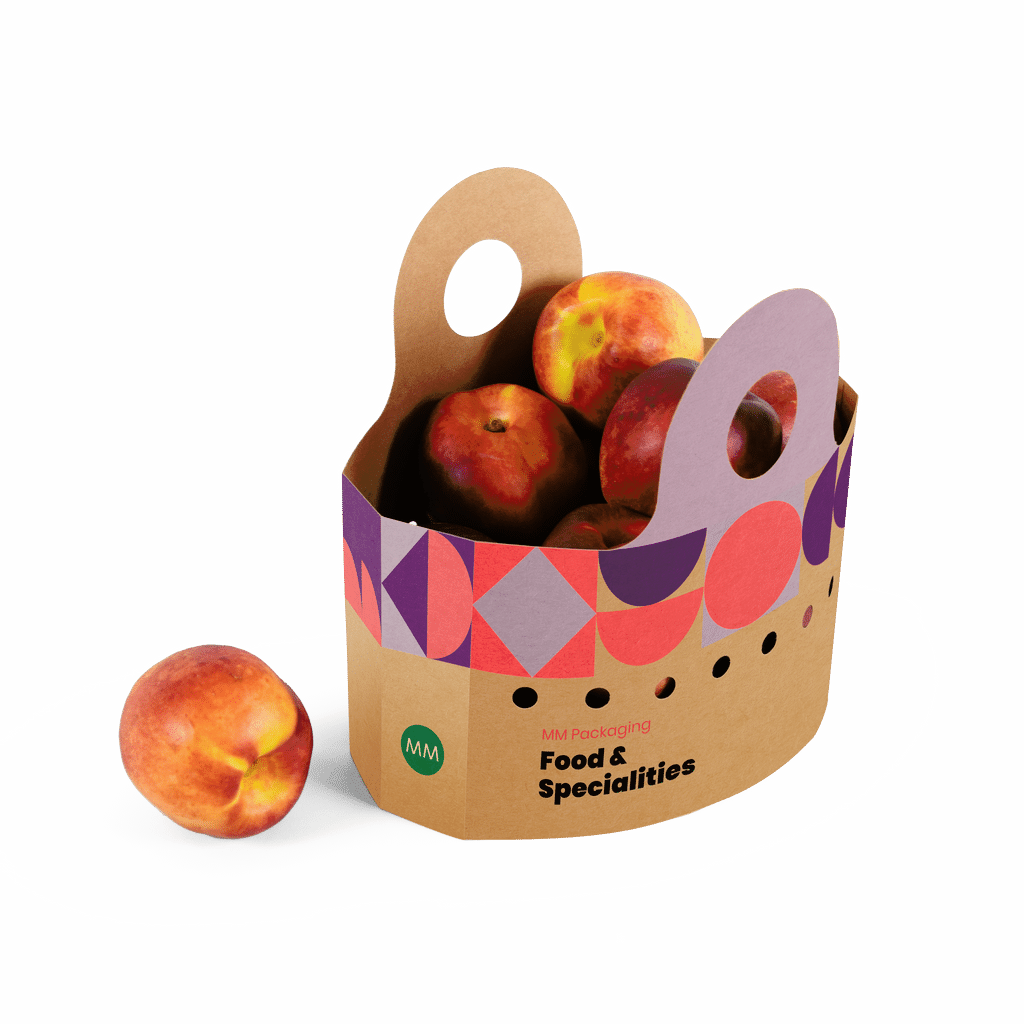

The session explored how fibre-based materials can support sustainability agendas while enabling high-speed processing, visual appeal and product protection. Participants looked at how key board properties, including stiffness, bulk, flatness and surface consistency affect performance in real life, from die-cutting and folding to printing and gluing.

The TPS team also shared insights into lightweighting opportunities. Using high-performance board grades with optimised strength-to-weight ratios, converters can reduce packaging weight without compromising on its integrity. This translates into cost savings and lower CO2 emissions across the value chain.

In practical terms, this means fewer misfeeds, cleaner die-cuts and reduced downtime on high-speed lines. It also helps improve print registration and glue application, resulting in better shelf impact and functional reliability.

The TPS team also shared insights into lightweighting opportunities. Using high-performance board grades with optimised strength-to-weight ratios, converters can reduce packaging weight without compromising on its integrity. This translates into cost savings and lower CO2 emissions across the value chain.