Foli and MM Board & Paper collaborate to optimise cartonboard sheeting and printing performance

A recent joint initiative between Foli ES, a leading packaging converter in Mexico, and MM Board & Paper has demonstrated the impact of close technical collaboration on improving production outcomes in cartonboard sheeting and printing processes.

In late June, MM Board & Paper’s Technical Product Service Manager Michael Zelingr visited Foli’s facilities to work alongside their in-house team in optimising performance on their sheeting and printing lines. The main objectives were to prevent surface marks while sheeting and delamination during offset printing.

Fine-tuning cartonboard sheeting and printing

The visit reflected a strong partnership rooted in shared expertise and trouble-shooting experience. To optimise sheeting performance the teams found new ways “to unwind” – or as it is known in the industry: to decurl cartonboard that has been rolled for bulk delivery. Fine-tuning led to an decurling process that did not compromise the cartonboard’s mechanical properties.

For offset printing, the teams first fine-tuned the ink mix being used. Then they determined the appropriate rubber blanket (hardness) condition to reduce the possibility of risk of delamination.

Drawing on their combined technical knowledge, they were able to adjust equipment settings and improve board performance to ensure stable, efficient line performance. Subsequent testing showed measurable gains in both output quality and run speed.

Enhancing laminated packaging with recycled cartonboard

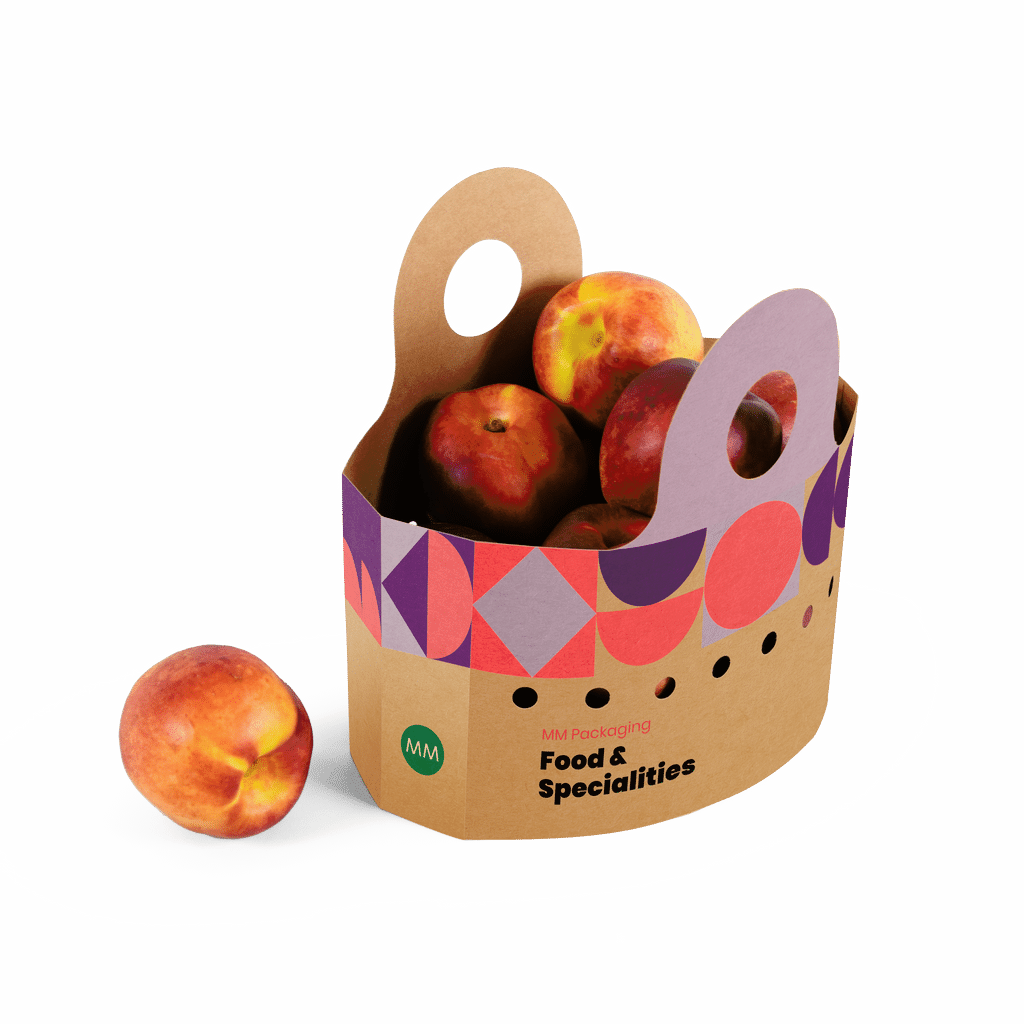

This collaboration also included a review of laminated packaging using MM’s MCM® recycled cartonboard. After a careful analysis, the partners determined enhancements to board specifications to better meet Foli’s lamination requirements going forward.

Proactive collaboration drives better packaging performance

In-person engagements like this highlight the value of open dialogue and a shared shift in mindset that thinks beyond reactive fixes and focuses instead on proactive improvements. As Zelingr noted, “At MM we believe efficiency and quality step changes happen best and fastest by walking the floor with our partners. Understanding our portfolio and seeing their machine park lets us make better packaging together.”

By continually improving cartonboard sheeting and printing services, Foli and MM Board & Paper demonstrate how hands-on technical fine-tuning and a proactive approach can lead to faster, more efficient converting processes and high-performance packaging solutions across Mexico and beyond.